CNC Machining has evolved into an important factor in modern engineering. It is transforming how we design and produce intricate components. CNC machines are able to achieve unsurpassed precision. From CNC Machines to CNC Mills, the world of industrial automation has been reshaped, and Australia stands at the forefront of this technological evolution.

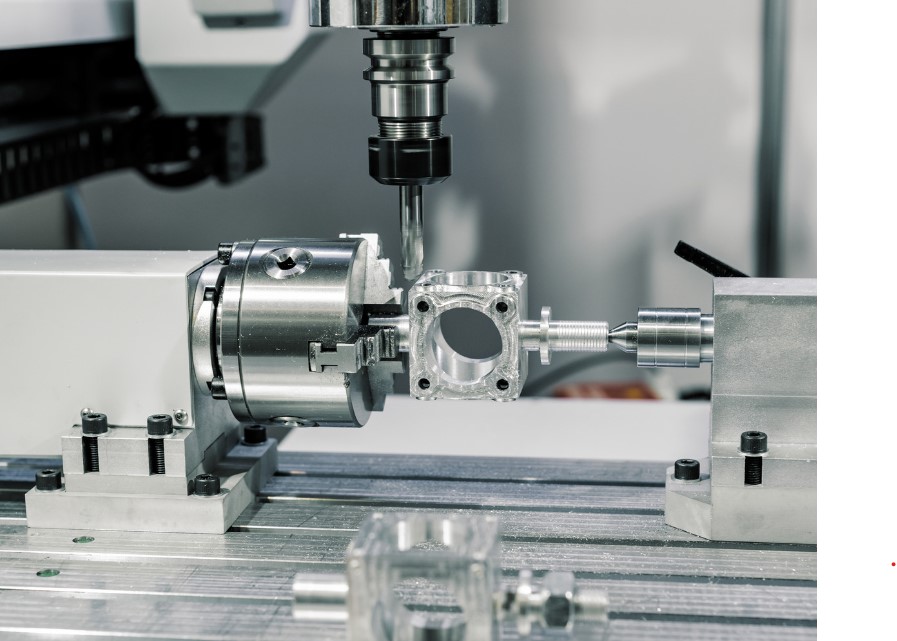

CNC machineries operate by applying the principles of subtractive manufacturing, distinguishing itself by removing material, rather than adding it, to sculpt raw materials into meticulously crafted completed parts. At the heart of this technology is the CNC Machine, a marvel of technology that has become the cornerstone of manufacturing precision.

CNC machines are controlled by digitalized computers, which automate, oversee and regulate the movement of industrial machines. The digital code guides the high-speed cutters of the machine to turn a solid object into the desired shape with the highest precision. This synergy is evident in larger industrial installations. It is a seamless integration of CNC Machines with computers increases productivity and efficiency.

The mechanics of CNC machining are intricate and fascinating. CNC Mills work with solid blocks of material to cut out intricate shapes using high-speed equipment. CNC machineries have unrivalled precision, which makes it the most preferred method for industries where precision is essential.

Australia’s CNC Machine market is thriving. A robust industrial sector and cutting-edge technology are driving the development. CNC Machine Australia is a center of technological advances, where industries ranging from electronics to aerospace and automotive harness the capabilities of CNC machine tools for unbeatable precision and efficiency.

CNC Mills have a major impact on the future manufacturing. They are controlled by computerized code and create precise parts for a variety of industries. CNC Mills are now indispensable tools for engineers and manufacturers because of their effectiveness and precision.

The advantages of CNC machine machining are numerous, extending far beyond traditional manufacturing methods. A key advantage is the capability of CNC machines to produce highly complex components as well as intricate designs, with consistent precision. CNC Machines are digital, which allows for rapid prototyping and reduces time and cost.

CNC Machine Tools also aid in the effectiveness of CNC machine. These tools encompass a variety of tools that assist in the machining process, from cutting and shaping to drilling and finishing. The combination of CNC Machines and CNC Machine Tools ensures an efficient workflow, increasing precision and minimizing waste.

CNC machining is a transformative technology that has gained popularity across industries. In the aerospace industry, CNC machining plays a crucial role in the creation of complex components that require the highest level of precision and dependability. CNC machining is an extremely efficient way to manufacture intricate parts, like machinery and infrastructure.

The flexibility of CNC machines is also evident in the electronics and automotive industries. CNC Machines can produce the complex components required for electronic gadgets, as well as the precision required in automotive engineering. CNC machineries can be utilized to make parts for engines as well as intricate electronic circuits.

CNC Machines (CNC Mills), CNC Machine Tools, and CNC Machines are the foundations of this technological revolution. The precision, versatility, and efficiency of CNC machining continues to define the future of Australia and beyond. It has paved the way to innovation and excellence in all industries.